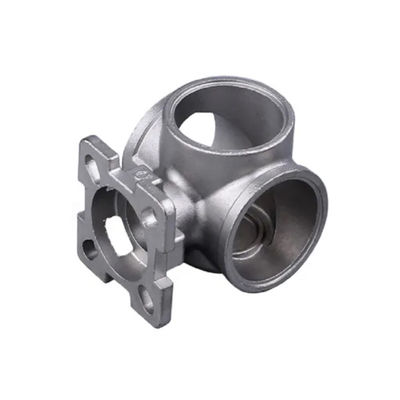

A floating design ball valve sandwiches the hollow ball between two or more cupped seats that form a tight seal between the body and the ball at the inlet and outlet ports of the valve body.

The ball is rotated (usually 90 degrees) by a shaft that protrudes outside of the valve body and is connected to some form of

operator. For this reason, most ball valves are referred to as quarter-turn valves. This shaft is not rigidly attached to the ball

in order for the ball to pivot on the end of the shaft as it rotates on the axis of the ball. This is usually accomplished with a slot on top of the ball, perpendicular to the ball’s flow path. The cupped portion of the seats cradle the ball prevents it from moving down in the valve body.

Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

SUBMIT

More information facilitates better communication.

Mr.

- Mr.

- Mrs.

OK

Submitted successfully!

We will call you back soon!

OK

Leave a Message

We will call you back soon!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!

SUBMIT